Wo ein Handschlag noch zählt.

Ihr Partner für

NE-Metalle & Stahl

Bornebusch ist seit über 30 Jahren der zuverlässige Partner aus dem Herzen des Siegerlandes, wenn es um die Beschaffung und Fertigung von Halbzeugen und mechanisch bearbeiteten Teilen aus NE-Metallen und Stahl geht. Seit jeher verlassen sich unsere Kunden in der ganzen Bundesrepublik und dem europäischen Ausland auf die Qualität von Bornebusch-Produkten – und das können Sie auch. Schließlich ist Zuverlässigkeit nicht nur irgendein Schlagwort für uns, sondern ein Grundpfeiler unserer Firmenphilosophie.

Und übrigens: Ab 2019 bietet unsere NE-Allianz Ihnen noch mehr Vorteile und Möglichkeiten – bei gleichbleibend erstklassiger Qualität!

Was spricht für

Bornebusch?

- Ehrlichkeit

- Zuverlässigkeit

- Partnerschaft

- Professionalität

- Fortschrittlichkeit

- Kompetenz

Kontaktieren Sie uns und überzeugen Sie sich selbst.

Wir beraten Sie gerne!

UNSERE LEISTUNGEN

Individuell abgestimmt, professionell umgesetzt.

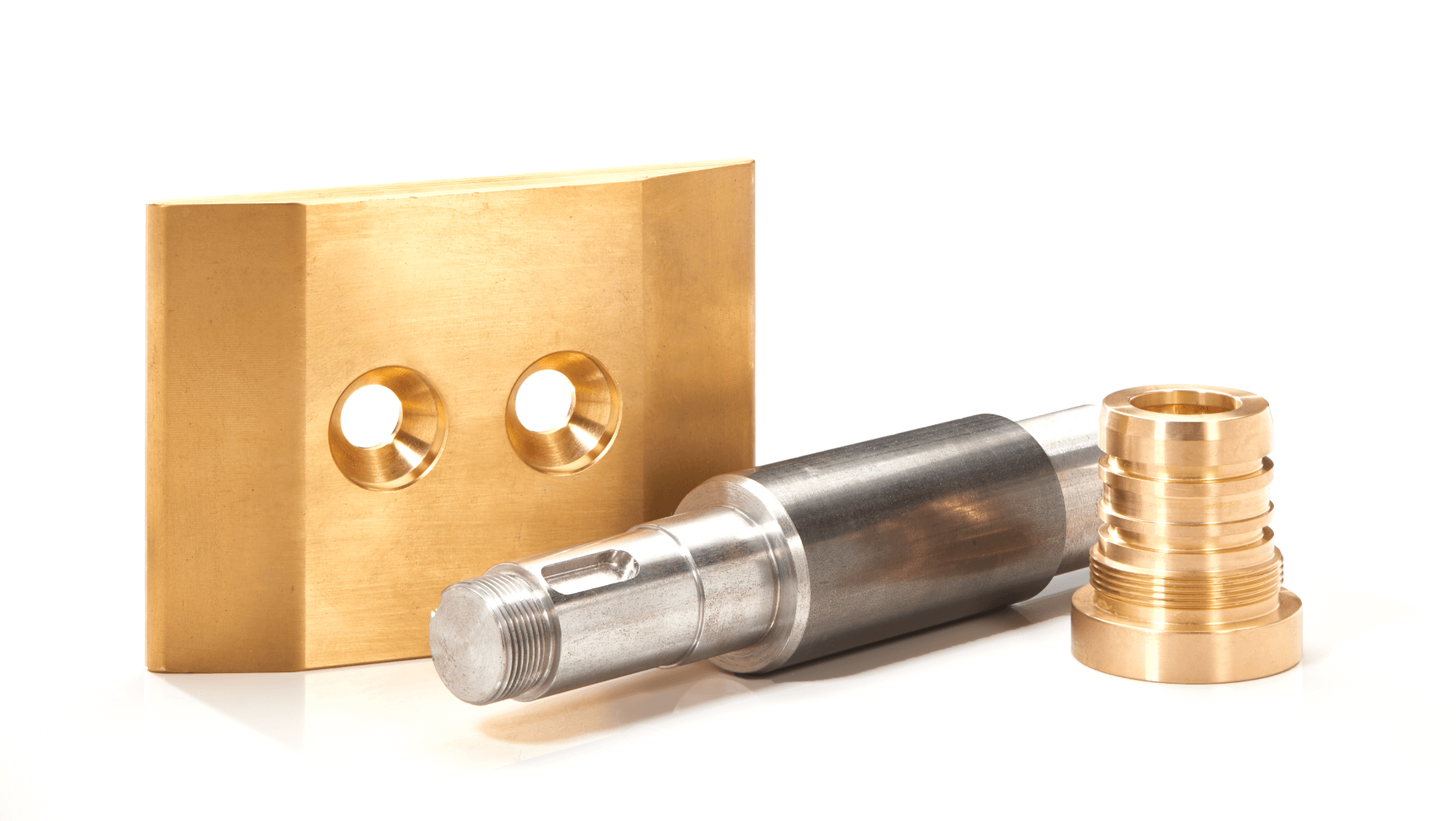

Lohnfertigung

Wir fertigen für Sie – inklusive Material oder mit Ihrer Beistellung – Einzelteile oder Serien aus NE-Metallen, Kunststoff oder Stahl bzw. allen gängigen Materialien. Bei uns sind Ihre CNC-Projekte in guten Händen.

Dimensionierungen

Bei uns profitieren Sie von einer riesigen Bandbreite: Wir bieten unsere Produkte beispielsweise in Größenbereichen von wenigen Millimetern bis zu 2.500 mm Ø an - für jede Anforderung die richtige Lösung.